【展商推荐】广骏新材料科技股份有限公司

广骏新材料科技股份有限公司

Gorgeous New Material Technology co., LTD. Profile

展位号:W5K60

2024年8月2日-4日

上海新国际博览中心

广骏新材料科技股份有限公司成立于2013年,是一家集新型建筑材料生产、研发、销售、技术咨询服务为一体的高新技术企业,拥有两大生产基地。公司始终围绕绿色建筑节能装饰材料和技术服务领域深耕近十年,产品应用已超过5000万平方米。辐射范围覆盖华北地区,并逐步向东北、西北发展,合作客户包括30多家国内知名的开发企业。

广骏自成立以来,先后被授予“高新技术企业”“河北省专精特新示范企业”“A级研发机构”“河北省园林式单位”,通过了ISO9001、ISO14001、ISO45001三大国际管理体系认证和安全生产标准化认证。重点研发的水性建筑多彩涂料体系,是外墙干挂石材、陶板、铝板的完美替代产品。重点推广的保温与结构一体化专利技术,适用于超低能耗建筑和各种民用建筑,解决了传统外墙保温着火、脱落的安全隐患。

广骏始终坚持创新发展,现与4家科研院校在材料研发、生产自动化等领域展开了产学研合作,拥有自主专利35项,并获批“河北省节能住宅保温材料技术创新中心”“石家庄市建筑节能材料技术创新中心”,研发费用投入连续3年达到营业收入的4%以上,“2021年河北省科技创新研发投入民营企业100佳名单”中排名第39名。产品通过了国家绿色建材标识认证,入围《被动式低能耗建筑产品选用目录》《雄安新区大宗建材集采目录》。

2022年,广骏打造了“碳中和建筑系统研发基地”,研发可广泛应用于被动式高层住宅、医院、学校、商业综合体、乡村节能美宅、零碳民宿的建筑技术,并陆续与河北省建筑设计研究院、北方工程设计研究院、石家庄市建筑设计院等在技术开发、标准制定、体系应用等方面展开多领域合作,聚智汇谋,共绘绿建蓝图。

发展装配式建筑,让老百姓住上舒适的房子,是中冀广骏践行绿色低碳发展理念的最佳实践之一。近年来中冀广骏积极推进装配式建筑技术,全面改善农房住宅的使用功能和居住体验,已拥有叠合钢网、珍珠岩复合保温板等多种成熟的绿色农房产品,积累了丰富的项目经验和技术成果,截至目前中冀广骏的主流住宅产品全面采用装配式的建造方式,共计完成约10万平米。

未来,广骏将不断加大产品的研发力度,持续深耕被动式超低能耗建筑领域,为我省建筑领域“碳达峰”贡献自己的一份力量。

Guangjun New Materials Technology Co., Ltd. was established in 2013. It is a high-tech enterprise that integrates the production, research and development, sales, and technical consulting services of new building materials, with two major production bases. The company has been deeply cultivating in the field of green building energy-saving decorative materials and technical services for nearly a decade, with product applications exceeding 50 million square meters. The radiation coverage covers the North China region and gradually develops towards the northeast and northwest, with cooperative clients including more than 30 well-known domestic development enterprises.

Since its establishment, Guangjun has been awarded the titles of "High tech Enterprise", "Hebei Province Specialized, Refined, Special and New Demonstration Enterprise", "A-level R&D Institution", and "Hebei Province Garden style Unit". It has passed the three major international management system certifications of ISO9001, ISO14001, and ISO45001, as well as the safety production standardization certification. The water-based building color coating system, which focuses on research and development, is a perfect substitute product for dry hanging stone, ceramic panels, and aluminum panels on exterior walls. The key promoted patented technology for integrated insulation and structure is suitable for ultra-low energy consumption buildings and various civil buildings, solving the safety hazards of traditional exterior wall insulation catching fire and falling off.

Guangjun has always adhered to innovative development and has cooperated with four scientific research institutions in the fields of material research and development, production automation, etc. It has 35 independent patents and has been approved as the "Hebei Province Energy saving Residential Insulation Material Technology Innovation Center" and "Shijiazhuang City Building Energy saving Material Technology Innovation Center". The R&D investment has reached over 4% of operating income for three consecutive years, ranking 39th in the "2021 Top 100 Private Enterprises Invested in Hebei Province's Science and Technology Innovation R&D". The product has passed the national green building material identification certification and has been shortlisted for the "Catalogue of Passive Low Energy Building Products Selection" and the "Catalogue of Bulk Building Materials Procurement in Xiong'an New District".

In 2022, Guangjun established a "Carbon Neutrality Building System Research and Development Base", which can be widely used in passive high-rise residential buildings, hospitals, schools, commercial complexes, rural energy-saving and beautiful homes, and zero carbon homestays. It has successively cooperated with Hebei Provincial Institute of Architectural Design and Research, Northern Engineering Design and Research Institute, Shijiazhuang City Institute of Architectural Design, etc. in various fields such as technology development, standard formulation, and system application, gathering wisdom and planning, and jointly drawing a green building blueprint.

Developing prefabricated buildings to provide comfortable housing for the people is one of the best practices for Zhongji Guangjun to implement the concept of green and low-carbon development. In recent years, Zhongji Guangjun has actively promoted prefabricated building technology, comprehensively improving the functionality and living experience of rural housing. It has developed various mature green rural housing products such as laminated steel mesh and perlite composite insulation board, and has accumulated rich project experience and technical achievements. As of now, the mainstream residential products in Zhongji Guangjun have adopted prefabricated construction methods, completing a total of about 100000 square meters.

In the future, Guangjun will continue to increase its product research and development efforts, continue to deepen its cultivation in the field of passive ultra-low energy buildings, and contribute to the "carbon peak" of the construction industry in our province.

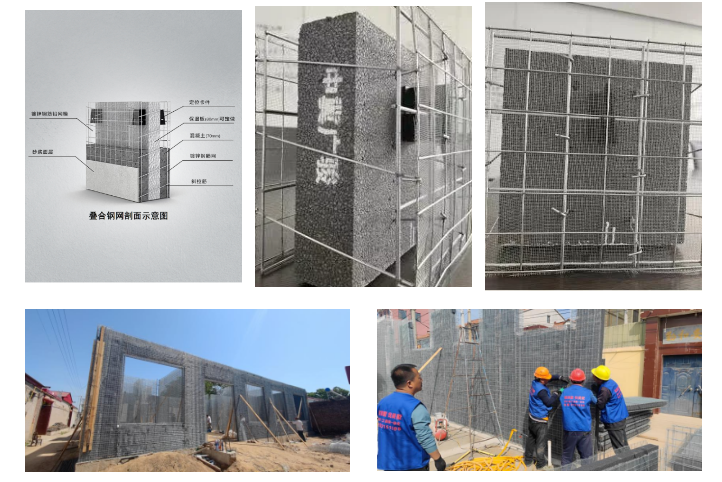

叠合钢网保温夹芯农房

Stacked steel mesh insulation sandwich farmhouse

叠合式钢丝网架夹芯板是在原有钢丝网架夹芯板的两侧叠合焊接钢丝免拆网模而成简称叠合钢网板,它作为钢丝网架水泥聚苯乙烯夹芯板二次研发产品,是符合国家墙改、节能政策鼓励发展的一种新型建筑材料。已经发展为集承重、保温、隔音、防潮一体化的新型建筑结构,技术规程参照《JGJ/T 273-2012》,实现了工厂化生产和施工装配化,同时形成了建筑节能一体化结构体系。

而且中冀广骏叠合钢网还拥有建造便捷迅速、结构安全抗震、性价比高、可视化浇筑、省时省工省力、防火可达A级、抗震极限可达8度、保温隔热、冬暖夏凉、隔音降噪等诸多优势。

Stacked steel wire mesh sandwich panel is a new type of building material that combines and welds steel wires on both sides of the original steel wire mesh sandwich panel without dismantling the mesh mold. As a secondary research and development product of steel wire mesh cement polystyrene sandwich panel, it is in line with national wall reform and energy-saving policies to encourage development. It has developed into a new type of building structure that integrates load-bearing, insulation, sound insulation, and moisture-proof. The technical specifications refer to JGJ/T 273-2012, achieving factory production and construction assembly, while forming an integrated structural system for building energy conservation.

Moreover, the Zhongji Guangjun composite steel mesh also has many advantages, such as convenient and rapid construction, structural safety and seismic resistance, high cost-effectiveness, visual pouring, time-saving, labor-saving, fire resistance up to A level, seismic limit up to 8 degrees, thermal insulation, warm winter and cool summer, sound insulation and noise reduction.

SLK 超低能耗点连内置保温体系

SLK ultra low energy point connection

with built insulation system

LK超低能耗点连式限位钢丝网片内置保温技术,(简称LK超低能耗点连内置保温体系)省去了主体浇筑后再进行双层保温施工的步骤,实现保温与结构一体化施工,彻底解决了传统超低能耗建筑外墙保温施工复杂、缓慢、管理成本高、不适用于高层建筑、存在脱落着火等安全隐患的弊端,实现建筑不拆,保温不坏。

LK ultra-low energy consumption point connected limited steel wire mesh built-in insulation technology (referred to as LK ultra-low energy consumption point connected built-in insulation system) eliminates the step of double-layer insulation construction after the main body is poured, realizes integrated construction of insulation and structure, and completely solves the drawbacks of complex, slow, high management cost, unsuitable for high-rise buildings, and safety hazards such as falling off and catching fire in traditional ultra-low energy building exterior wall insulation construction. It realizes that the building is not dismantled and the insulation is not damaged.

点连式钢丝网膨胀珍珠岩

Point connected steel wire mesh expanded perlite

点连式钢丝网膨胀珍珠岩复合保温板系统分为两个子系统:

点连式钢丝网珍珠岩复合保温板梁柱系统:由抗裂层、抹面层、点连式钢丝网膨胀珍珠岩复合保温板(Ⅰ型复合保温板)和锚固件等构成。点连式钢丝网膨胀珍珠岩复合保温板与钢筋混凝土框架结构、钢结构建筑的梁或柱通过锚固件连接,再在点连式膨胀钢丝网珍珠岩复合保温板外侧做抹面层、抗裂层和饰面层的外墙保温构造。简称梁柱系统。

点连式钢丝网珍珠岩复合保温板围护墙系统:以钢筋混凝土框架结构、钢结构建筑主体承重构件为支承,通过预埋插筋、植筋或焊接短筋方式将点连式钢丝网膨胀珍珠岩复合保温板(Ⅱ型复合保温板)与钢筋混凝土或钢结构梁柱连接,在复合保温板两侧喷涂砂浆抹面层、做抗裂层和饰面层的保温构造。简称围护墙系统。

The point connected steel wire mesh expanded perlite composite insulation board system is divided into two subsystems:

Point connected steel wire mesh perlite composite insulation board beam column system: composed of crack resistant layer, plastering layer, point connected steel wire mesh expanded perlite composite insulation board (Type I composite insulation board) and anchoring components. The point connected steel wire mesh expanded perlite composite insulation board is connected to the beams or columns of reinforced concrete frame structures and steel structure buildings through anchoring components. Then, the exterior wall insulation structure is constructed with a plaster layer, crack resistance layer, and decorative layer on the outer side of the point connected expanded steel wire mesh perlite composite insulation board. Abbreviated as beam column system.

Point connected steel wire mesh perlite composite insulation board enclosure wall system: Supported by reinforced concrete frame structure and steel structure building main load-bearing components, the point connected steel wire mesh expanded perlite composite insulation board (Type II composite insulation board) is connected to reinforced concrete or steel structure beams and columns through pre embedded reinforcement, planting reinforcement or welding short reinforcement. The insulation structure is sprayed with mortar plaster layer, crack resistance layer, and decorative layer on both sides of the composite insulation board. Abbreviated as enclosure wall system.

产品销售范围及对象

公司产品广泛应用于被动式高层住宅、医院、学校、商业综合体、乡村节能美宅、零碳民宿等多种建筑。