【展商推荐】青岛青力环保设备有限公司

青岛青力环保设备有限公司

Qindao Qingli Environmental Protection Equipment Co., Ltd.

展位号:W5C23

2024年8月2日-4日

上海新国际博览中心

青岛青力环保设备有限公司

青岛青力环保设备有限公司始建于1958年,1999年由国营企业改制为民营股份制,位于山东省青岛胶州市。公司专注于岩棉智能生产线装备等环保专用装备的研发与生产,是国内第一家热质熔渣制岩棉云端智能生产线研制企业,设备在国内已经成功运行100多条,已被认定为山东省重大“首台套”,并出口至俄罗斯、保加利亚、印度、越南等多个国家。截止目前,青力自主研发的热质熔渣制岩棉生产线市场占有率90%,已连续五年在国内名列前茅。

“推动行业进步、实现员工梦想”是公司的发展目标,创新使企业行稳致远。青力公司联合中国科学院地质与地球物理研究所、北京科技大学、东北大学等多所科研院校开展产学研合作,共同成立了热熔渣联合实验室、刘嘉麒院士工作站等多个研发平台,深入研发热熔渣能质协同综合利用制备岩棉工艺、技术与装备。目前企业通过了ISO质量、环境、职业健康管理体系认证,承担了国家“科技创新基金”项目2项,荣获了国家第二批专精特新“小巨人”企业、国家第三批高质量发展专精特新“小巨人”企业、山东省企业技术中心、山东省制造业单项冠军、山东省“首台套”重大技术装备、山东省专精特新企业、青岛市隐形冠军等多项荣誉。

The company was established in 1958 as a state owned enterprise and a large scale manufacturer of iron melting furnaces for the metallurgy.In 1999, it transformed into a privately-owned enterprise.Nowadays, Qingdao Qingli Environmental Protection Equipment Co., Ltd. is one of the leading manufacturers of Rock Wool (Stone Wool)and Mineral Wool Production Lines in China. Our quality of manufacturing and stability of machines' performance are at a worldwide level. Energy efficiency and the protection of the environment are two of the main aspects we strongly consider when manufacturing our equipment.The equipment is exported to Russia, Bulgaria, Vietnam, India, Uzbekistan, Kazakhstan, Türkiye and other countries.

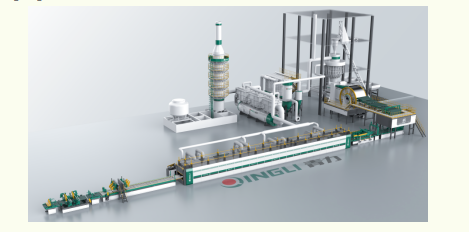

冷渣岩棉生产线

原材料通过称重和给料系统以正确的顺序和比例供给冲天炉(或电炉),熔化后流股,流向离心机。通过离心机将熔化的材料转化成薄纤维。再经过集棉机把纤维收集通过过渡皮带机输送到摆锤,通过摆锤的摆动改变纤维的方向在成型机上形成多层叠的纤维毡层。再通过打褶加压机,用于定向纤维,给予产品高机械性能,毛毡被送到固化炉,在那里粘合剂固化,最终达到产品所需的厚度。岩棉产品,从固化炉出来,通过冷却、两边修剪、纵切、横切达到要求的尺寸,最后产品堆放在包装段进行成品包装。

Cold slag rock wool production line

The raw materials are fed to the cupola (or electric furnace) in the correct sequence and proportions through a weighing and feeding system, and the melted stream flows to the centrifuge. The molten material is converted into thin fibers through a centrifuge. The fiber is collected by the cotton collector and transported to the pendulum through the transition belt conveyor. The direction of the fiber is changed by the swing of the pendulum to form multi-layered fiber mat layers on the forming machine. After passing through a pleating press, which is used to orient the fibers and give the product high mechanical properties, the felt is sent to a curing oven where the adhesive cures and finally reaches the required thickness of the product. Rock wool products come out of the curing furnace and reach the required size through cooling, trimming on both sides, longitudinal cutting, and cross-cutting. Finally, the products are stacked in the packaging section for finished product packaging.

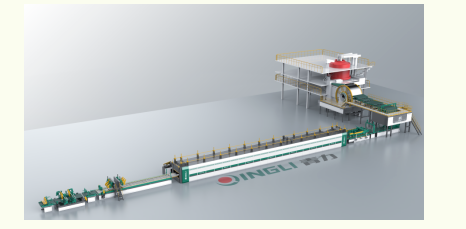

热熔渣岩棉生产线

1300-1350℃的热态渣通过渣包运到岩棉车间,由吊车吊运渣包倾倒到电炉内,然后在电炉内保温升温后,达到需要温度的流股,流向离心机。通过离心机将熔化的材料转化成薄纤维。再经过集棉机把纤维收集通过过渡皮带机输送到摆锤,通过摆锤的摆动改变纤维的方向在成型机上形成多层叠的纤维毡层。再通过打褶加压机,用于定向纤维,给予产品高机械性能,毛毡被送到固化炉,在那里粘合剂固化,最终达到产品所需的厚度。岩棉产品,从固化炉出来,通过冷却、两边修剪、纵切、横切达到要求的尺寸,最后产品堆放在包装段进行成品包装。

The hot slag at 1300-1350℃ is transported to the rock wool workshop through slag bags. The slag bags are lifted by a crane and dumped into the electric furnace. Then, after being insulated and heated in the electric furnace, the stream reaches the required temperature and flows to the centrifuge. The molten material is converted into thin fibers through a centrifuge. The fiber is collected by the cotton collector and transported to the pendulum through the transition belt conveyor. The direction of the fiber is changed by the swing of the pendulum to form multi-layered fiber mat layers on the forming machine. After passing through a pleating press, which is used to orient the fibers and give the product high mechanical properties, the felt is sent to a curing oven where the adhesive cures and finally reaches the required thickness of the product. Rock wool products come out of the curing furnace and reach the required size through cooling, trimming on both sides, longitudinal cutting, and cross-cutting. Finally, the products are stacked in the packaging section for finished product packaging.

产品销售范围及对象

国内外岩棉厂家

2024亚洲保温展预登记通道开启

扫码登记 预约参观参会

TIM EXPO

亚洲保温展,为碳中和而行!

· TIM Expo项目组 ·

参展咨询

抢位热线:021-5109 7799

邮箱:info@zhanye-expo.com

参观咨询/市场合作

电话: 021-5109 7799

邮箱: nicoleshen@zhanye-expo.com

“

官方微信

扫码关注我们

“

官方抖音

保存二维码跳转关注

“

展会小助手

加入行业交流群